Likarolo tse ngata tsali-gear tse ncha tsa ho fokotsa matlalelikere tsa likoloiMorero o hloka ho ntsha meno ka mora ho sila dikere, e leng se tla senya boleng ba bokaholimo ba leino, mme se be se ame le tshebetso ya NVH ya sistimi. Pampiri ena e ithuta ho tshabeha ha bokaholimo ba leino ba maemo a fapaneng a tshebetso ya ho ntsha meno ka mora ho ntsha meno le dikarolo tse fapaneng pele le ka mora ho ntsha meno ka mora ho ntsha meno. Diphetho di bontsha hore ho ntsha meno ka mora ho ntsha meno ho tla eketsa ho tshabeha ha bokaholimo ba leino, ho angwang ke dibopeho tsa dikarolo, diparamitha tsa tshebetso ya ho ntsha meno ka mora ...

Tlas'a semelo se kaholimo, pampiri ena e tšohla lintlha tse tharo tse latelang:

Tšusumetso ea liparamente tsa ts'ebetso ea ho ntša meno ka lithupa holim'a ho hlaka ha bokaholimo ba meno;

Tekanyo ea ho holisa meno ka ho hlaba ha bokaholimo ba meno tlas'a maemo a teng a ts'ebetso ea tlhahiso ea sehlopha;

Tšusumetso ea keketseho ea ho khopama ha bokaholimo ba meno ts'ebetsong ea NVH le mehato ea ho ntlafatsa ho khopama ha meno kamora ho ntša metsi ka ente.

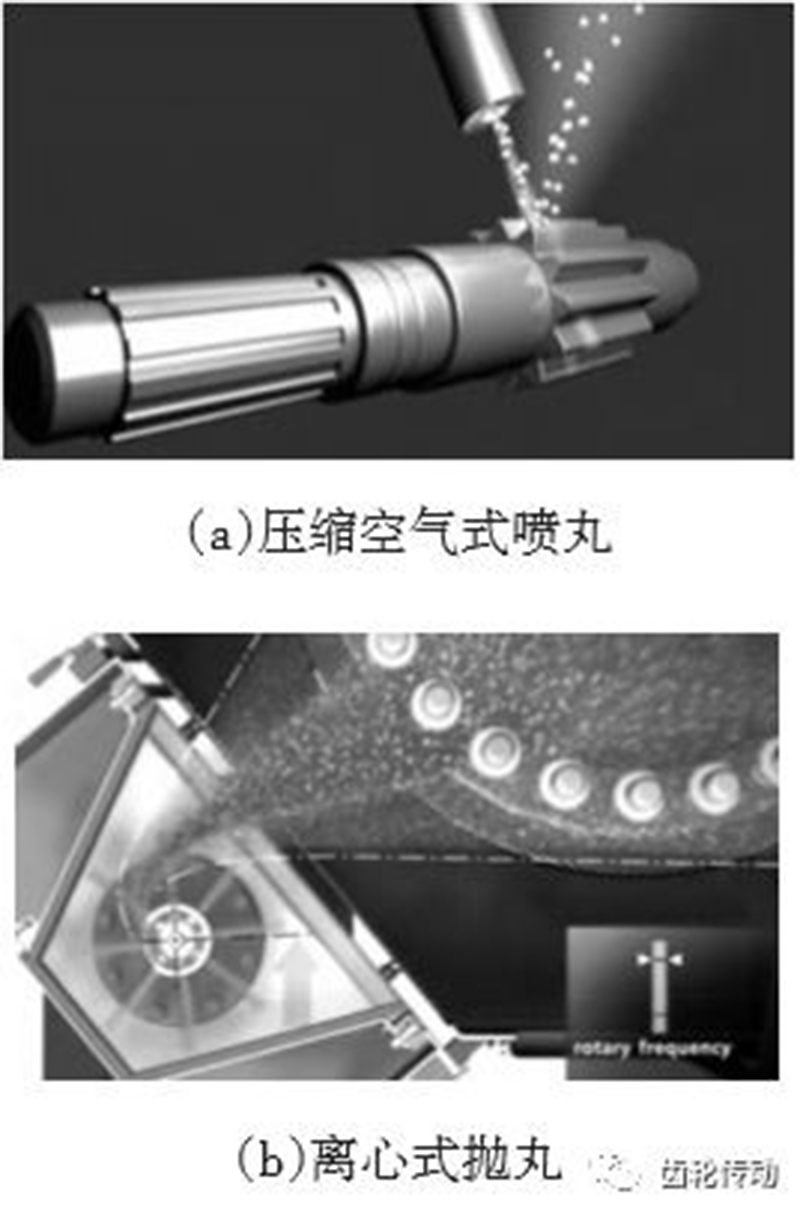

Ho ntsha dithunya ho bolela tshebetso eo ho yona dithunya tse ngata tse nyane tse nang le bothata bo boholo le motsamao o potlakileng di otlang bokahodimo ba dikarolo. Tlasa tshusumetso e potlakileng ya projectile, bokahodimo ba karolo bo tla hlahisa dikoti mme ho tla etsahala phetoho ya polasetiki. Mekgatlo e potileng dikoti e tla hanela phetoho ena mme e hlahise kgatello e setseng. Ho kopana ha dikoti tse ngata ho tla etsa lera le tshwanang la kgatello e setseng bokahodimong ba karolo, ka hona ho ntlafatsa matla a mokhathala a karolo. Ho ya ka tsela ya ho fumana lebelo le phahameng ka ho thunya, ho ntsha dithunya hangata ho arotswe ka ho ntsha dithunya tsa moya o hatelletsoeng le ho ntsha dithunya tsa centrifugal, jwalo ka ha ho bontshitswe ho Setshwantsho sa 1.

Ho ntsha moea o hatelletsoeng ho nka moya o hatelletsoeng e le matla a ho fafatsa thunya e tsoang sethunyeng; Ho ntsha sethunya sa centrifugal ho sebedisa enjene ho kganna impeller ho potoloha ka lebelo le phahameng ho lahlela thunya. Diparamitha tsa bohlokwa tsa tshebetso ya ho ntsha sethunya di kenyeletsa matla a ho tlala, ho kwahela le thepa e mahareng ya ho ntsha sethunya (thepa, boholo, sebopeho, thata). Matla a ho tlala ke paramethara e hlalosang matla a ho ntsha sethunya, a bontshwang ke bophahamo ba arc (ke hore, tekanyo ya ho kobeha ha karolo ya teko ya Almen kamora ho ntsha sethunya); Sekgahla sa ho kwahela se bolela karolelano ya sebaka se kwahetsweng ke mokoti kamora ho ntsha sethunya ho ya sebakeng sohle sa sebaka se ntsha sethunya; Mechini e sebediswang hangata ya ho ntsha sethunya e kenyeletsa thunyo ya terata ya tshepe, thunyo ya tshepe e entsweng ka foreimi, thunyo ya ceramic, thunyo ya khalase, jj. Boholo, sebopeho le thata ya mechini e ntsha sethunya di na le maemo a fapaneng. Ditlhoko tse akaretsang tsa tshebetso bakeng sa dikarolo tsa shaft ya gear ya phetisetso di bontshitswe ho Tafole ya 1.

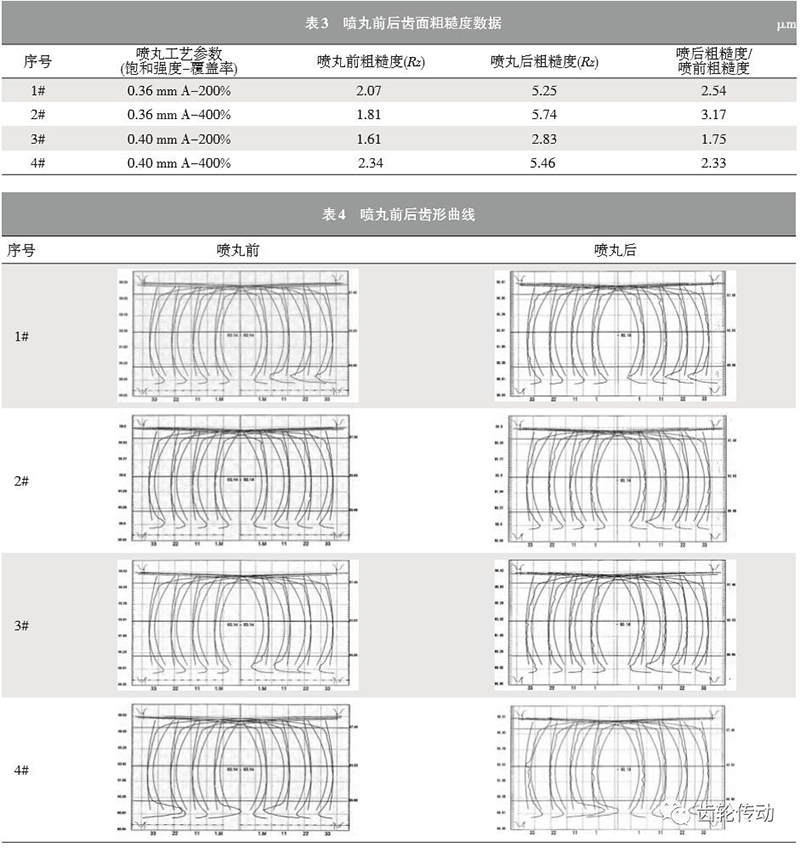

Karolo ea teko ke gear ea shaft e mahareng ea 1/6 ea projeke ea hybrid. Sebopeho sa gear se bontšitsoe ho Setšoantšo sa 2. Kamora ho sila, sebopeho sa bokaholimo ba leino ke Sehlopha sa 2, boima ba bokaholimo ke 710HV30, 'me botebo bo sebetsang ba lera la ho thatafatsa ke 0.65mm, tsohle li latela litlhoko tsa tekheniki. Ho ba thata ha bokaholimo ba leino pele ho ho phunya ho bontšitsoe ho Tafole ea 3, 'me ho nepahala ha boemo ba leino ho bontšitsoe ho Tafole ea 4. Ho ka bonoa hore ho ba thata ha bokaholimo ba leino pele ho ho phunya ho hotle, 'me mothinya oa boemo ba leino o boreleli.

Morero oa teko le liparamente tsa teko

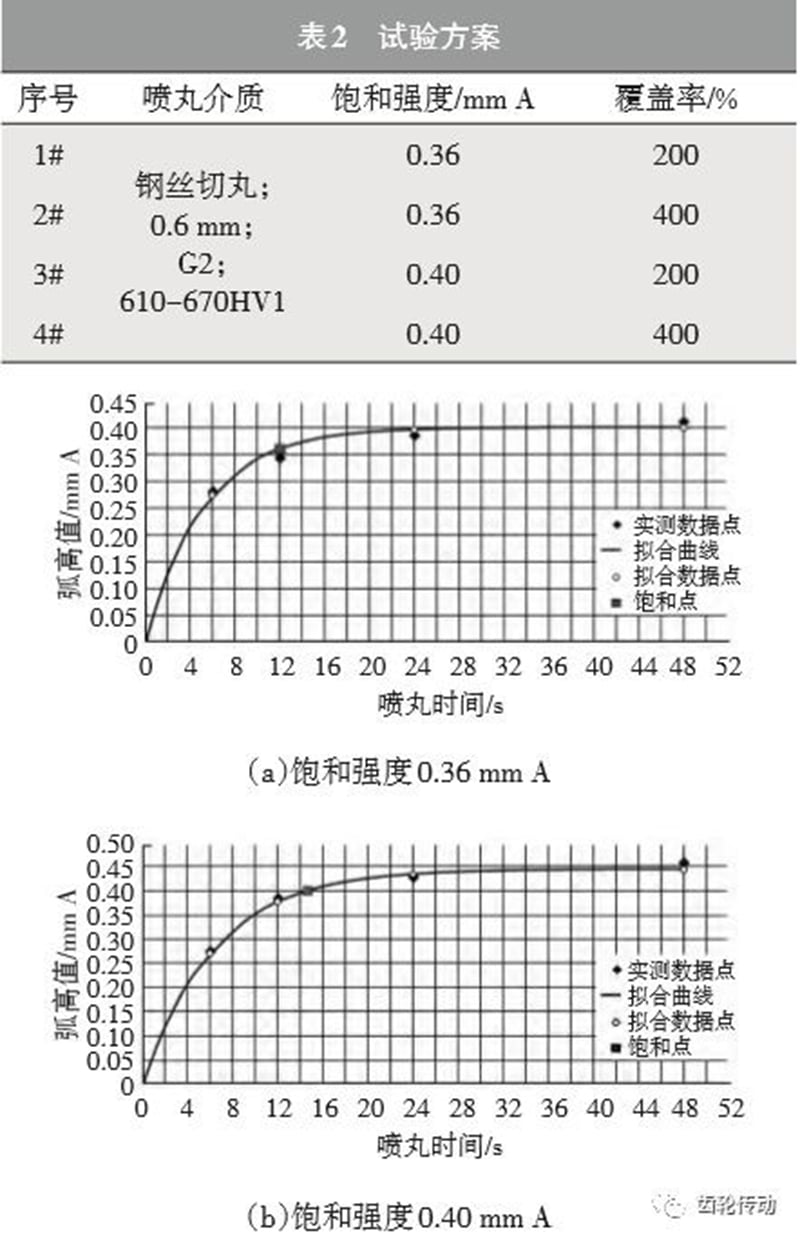

Mochini o hatelletsoeng oa ho ntša moea o hatelletsoeng o sebelisoa tekong. Ka lebaka la maemo a teko, ho ke ke ha khoneha ho netefatsa tšusumetso ea thepa ea bohareng ba ho ntša metsi ka lithunya (thepa, boholo, thata). Ka hona, litšobotsi tsa bohareng ba ho ntša metsi ka lithunya li lula li le teng tekong. Ke tšusumetso feela ea matla a ho tlatsa le ho koahela holim'a ho hlaka ha bokaholimo ba leino ka mor'a ho ntša metsi ka lithunya e netefalitsoeng. Sheba Tafole ea 2 bakeng sa moralo oa teko. Ts'ebetso e ikhethileng ea ho fumana liparamente tsa teko ke e latelang: taka sekhutlo sa ho tlatsa (Setšoantšo sa 3) ka teko ea setlankane sa Almen ho fumana ntlha ea ho tlatsa, e le ho notlela khatello ea moea o hatelletsoeng, phallo ea tšepe ea ho ntša metsi, lebelo la ho tsamaea ha nozzle, sebaka sa nozzle ho tloha likarolong le liparamente tse ling tsa lisebelisoa.

sephetho sa teko

Lintlha tsa ho hlaka ha bokaholimo ba leino ka mor'a ho ntsha meno li bontšitsoe ho Tafole ea 3, 'me ho nepahala ha boemo ba leino ho bontšitsoe ho Tafole ea 4. Ho ka bonoa hore tlas'a maemo a mane a ho ntsha meno, ho hlaka ha bokaholimo ba leino hoa eketseha 'me sekhutlo sa boemo ba leino se ba sekoti le se kobehileng ka mor'a ho ntsha meno. Karolelano ea ho hlaka ha leino ka mor'a ho fafatsa le ho hlaka pele le fafatsa e sebelisoa ho hlalosa ho holisa ho hlaka (Tafole ea 3). Ho ka bonoa hore ho holisa ho hlaka ho fapane tlas'a maemo a mane a ts'ebetso.

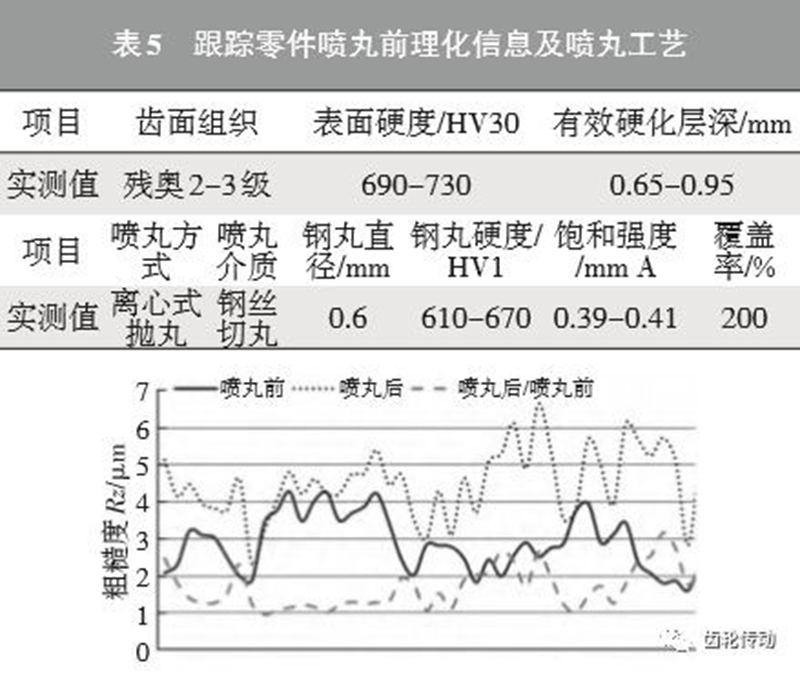

Ho Latela Sehlopha sa Kgodiso ya Bokgoni ba Leino ka ho Hlakola ka Shot

Liphetho tsa liteko Karolong ea 3 li bontša hore ho se tsitse ha bokaholimo ba leino ho eketseha ka maemo a fapaneng kamora ho ntsha meno ka mekhoa e fapaneng. E le ho utloisisa ka botlalo keketseho ea ho ntsha meno ka ho se tsitse ha bokaholimo ba leino le ho eketsa palo ea lisampole, lintho tse 5, mefuta e 5 le likarolo tse 44 ka kakaretso, li khethiloe ho latela ho se tsitse pele le kamora ho ntsha meno tlas'a maemo a tlhahiso ea sehlopha ts'ebetso ea ho ntsha meno ka ho se tsitse. Sheba Tafole ea 5 bakeng sa tlhahisoleseling ea 'mele le ea lik'hemik'hale le tlhahisoleseling ea ts'ebetso ea ho ntsha meno ka ho se tsitse ha likarolo tse lateloang kamora ho sila li-gear. Lintlha tsa ho se tsitse le ho holisa bokaholimo ba leino le ka pele le ka morao pele ho ntsha meno li bontšitsoe ho Setšoantšo sa 4. Setšoantšo sa 4 se bontša hore mefuta ea ho se tsitse ha bokaholimo ba leino pele ho ntsha meno ke Rz1.6 μ m-Rz4.3 μ m; Kamora ho ntsha meno ka ho se tsitse, ho se tsitse hoa eketseha, 'me sebaka sa kabo ke Rz2.3 μ m-Rz6.7 μ m; Ho se tsitse ho hoholo ho ka eketsoa ho fihlela makhetlo a 3.1 pele ho ntsha meno ka ho se tsitse.

Mabaka a susumetsang ho ba thata ha bokaholimo ba leino ka mor'a ho ntša leino ka ente

Ho ka bonoa ho tsoa molao-motheong oa ho ntša peo ka ho thunya hore ho thatafala ho hoholo le ho thunya ka lebelo le phahameng ho siea masoba a mangata holim'a karolo, e leng mohloli oa khatello e setseng ea khatello. Ka nako e ts'oanang, masoba ana a tla eketsa ho hlaka ha bokaholimo. Litšobotsi tsa likarolo pele ho ntša peo ka ho thunya le liparamente tsa ts'ebetso ea ho ntša peo ka ho thunya li tla ama ho hlaka kamora ho ntša peo ka ho thunya, joalo ka ha ho thathamisitsoe ho Tafole ea 6. Karolong ea 3 ea pampiri ena, tlas'a maemo a mane a ts'ebetso, ho hlaka ha bokaholimo ba leino kamora ho ntša peo ka ho thunya ho eketseha ho isa maemong a fapaneng. Tekong ena, ho na le lintho tse peli tse fapaneng, e leng, ho hlaka ha pele ho thunya le liparamente tsa ts'ebetso (matla a ho tlala kapa sekoahelo), tse ke keng tsa fumana ka nepo kamano pakeng tsa ho hlaka ha ho ntša peo ka mor'a ho thunya le ntlha e 'ngoe le e 'ngoe e susumetsang. Hona joale, litsebi tse ngata li entse lipatlisiso ka sena, 'me li hlahisitse mohlala oa khopolo-taba oa ho bolela esale pele ho hlaka ha bokaholimo kamora ho ntša peo ka ho thunya ho latela ketsiso ea likarolo tse lekanyelitsoeng, e sebelisoang ho bolela esale pele boleng bo lumellanang ba ho hlaka ha mekhoa e fapaneng ea ho ntša peo ka ho thunya.

Ho latela phihlelo ea 'nete le lipatlisiso tsa litsebi tse ling, mekhoa ea tšusumetso ea lintlha tse fapaneng e ka hakanngoa joalo ka ha ho bontšitsoe ho Tafole ea 6. Ho ka bonoa hore ho rarahana ka mor'a ho ntša peo ho angoa ka botlalo ke lintlha tse ngata, tseo hape e leng lintlha tsa bohlokoa tse amang khatello ea khatello e setseng. E le ho fokotsa ho rarahana ka mor'a ho ntša peo ka lebaka la ho netefatsa khatello e setseng ea khatello, ho hlokahala liteko tse ngata tsa ts'ebetso ho ntlafatsa motsoako oa liparamente khafetsa.

Tšusumetso ea ho hlaka ha bokaholimo ba meno ts'ebetsong ea NVH ea sistimi

Likarolo tsa gear li tsamaisong ea phetiso e matla, 'me ho teteana ha bokaholimo ba leino ho tla ama ts'ebetso ea bona ea NVH. Liphetho tsa liteko li bontša hore tlas'a mojaro le lebelo le tšoanang, ha ho teteana ha bokaholimo ho le hoholo, ho thothomela le lerata la sistimi ho ba hoholo; Ha mojaro le lebelo li eketseha, ho thothomela le lerata li eketseha ka ho hlaka haholoanyane.

Lilemong tsa morao tjena, merero ea lisebelisoa tse ncha tsa ho fokotsa matla e eketsehile ka potlako, 'me e bontša mokhoa oa nts'etsopele oa lebelo le phahameng le torque e kholo. Hona joale, torque e phahameng ka ho fetisisa ea sesebelisoa sa rona se secha sa ho fokotsa matla ke 354N · m, 'me lebelo le phahameng ka ho fetisisa ke 16000r/min, e tla eketsoa ho feta 20000r/min nakong e tlang. Tlas'a maemo a joalo a ts'ebetso, tšusumetso ea keketseho ea ho hlaka ha bokaholimo ba meno ts'ebetsong ea NVH ea sistimi e tlameha ho nahanoa.

Mekhoa ea ntlafatso bakeng sa ho khopama ha bokaholimo ba leino ka mor'a ho ntša ente

Mokhoa oa ho ntša meno ka mor'a ho sila li-gear o ka ntlafatsa matla a mokhathala a ho kopana le bokaholimo ba leino la gear le matla a mokhathala a kobehileng a motso oa leino. Haeba mokhoa ona o lokela ho sebelisoa ka lebaka la mabaka a matla ts'ebetsong ea moralo oa li-gear, e le ho nahana ka ts'ebetso ea NVH ea sistimi, ho hlaka ha bokaholimo ba leino la gear kamora ho ntša meno ka ho thunya ho ka ntlafatsoa ho latela lintlha tse latelang:

a. Ntlafatsa diparamente tsa tshebetso ya ho ntsha meno ka ho ntsha, mme o laole ho hodiswa ha bokahodimo ba meno ka mora ho ntsha meno ka motheo wa ho netefatsa kgatello e setseng. Sena se hloka diteko tse ngata tsa tshebetso, mme ho tenyetseha ha tshebetso ha ho matla.

b. Mokhoa oa ho ntša peo ka har'a lithupa o sebelisoa, ke hore, ka mor'a hore matla a tloaelehileng a ho ntša peo ka har'a lithupa a phethoe, ho eketsoa peo e 'ngoe hape. Matla a eketsehileng a ts'ebetso ea ho ntša peo ka har'a lithupa hangata a manyane. Mofuta le boholo ba thepa ea ho ntša peo li ka fetoloa, joalo ka peo ea ceramic, peo ea khalase kapa peo ea tšepe e khaotsoeng ka terata e nyane.

c. Kamora ho ntša metsi ka ente, ho eketsoa mekhoa e kang ho bentša bokaholimo ba meno le ho honola meno ka bolokolohi.

Pampiring ena, ho ithutoa ho ba thata ha bokaholimo ba leino la maemo a fapaneng a ts'ebetso ea ho ntša meno le likarolo tse fapaneng pele le ka mor'a ho ntša meno, 'me liqeto tse latelang li etsoa ho latela lingoliloeng:

◆ Ho ntsha meno ka leno ho tla eketsa ho hlaka ha bokaholimo ba leino, e leng se angoang ke litšobotsi tsa likarolo pele ho ntsha meno ka leno, liparamente tsa ts'ebetso ea ho ntsha meno ka leno le lintlha tse ling, 'me lintlha tsena le tsona ke lintlha tsa bohlokoa tse amang khatello e setseng ea khatello;

◆ Tlas'a maemo a teng a tlhahiso ea sehlopha, ho ba thata ha bokaholimo ba leino ka mor'a ho ntša pente ke makhetlo a 3.1 ho feta pele ho ntša pente;

◆ Keketseho ea ho thothomela ha bokaholimo ba meno e tla eketsa ho thothomela le lerata la sistimi. Ha torque le lebelo li le kholoanyane, keketseho ea ho thothomela le lerata e totobetse haholoanyane;

◆ Ho ba thata ha bokaholimo ba leino ka mor'a ho ntša meno ho ka ntlafatsoa ka ho ntlafatsa liparamente tsa ts'ebetso ea ho ntša meno, ho ntša meno ka motsoako, ho eketsa ho bentša kapa ho honola mahala ka mor'a ho ntša meno, jj. Ho ntlafatsoa ha liparamente tsa ts'ebetso ea ho ntša meno ho lebelletsoe ho laola keketseho ea ho ba thata ho fihlela makhetlo a ka bang 1.5.

Nako ea poso: Pulungoana-04-2022