LisebelisoaPhetoho ea boemo ba meno ke karolo ea bohlokoa ea moralo oa li-gear, e ntlafatsang ts'ebetso ka ho fokotsa lerata, ho thothomela le khatello ea maikutlo. Sengoloa sena se tšohla lipalo tsa bohlokoa le lintho tse amehang ho raleng li-gear profiles tse fetotsoeng.

1. Morero oa Phetoho ea Profaele ea Leino

Phetoho ea boemo ba meno e etsoa haholo-holo ho lefella ho kheloha ha tlhahiso, ho se lumellane hantle le ho fetoha ha elastic tlas'a mojaro. Lipheo tse ka sehloohong li kenyelletsa:

- Ho fokotsa liphoso tsa phetisetso

- Ho fokotsa lerata la lisebelisoa le ho thothomela

- Ho ntlafatsa kabo ea mojaro

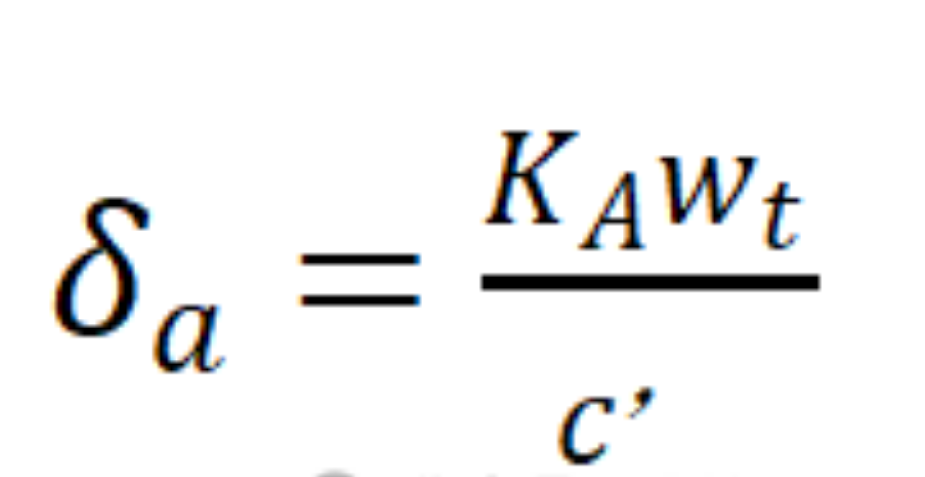

- Ho eketsa nako ea bophelo ba gear Ho ea ka tlhaloso ea ho tiea ha meshing ea gear, ho tenyetseha ha elastic ha meno a gear ho ka hakanngoa ka mokhoa o latelang: δa – deformation ea elastic ea leino, μm; KA – Use factor, sheba ISO6336-1; wt – moroalo ka yuniti bophara ba leino, N/mm,wt=Ft/b; Ft – matla a tangential holim'a gear, N; b – bophara ba leino bo sebetsang ba gear, mm; c '- ho tiea ha letlooeng la leino la para e le 'ngoe, N/(mm·μm); cγ – Ho tiea ha letlooeng ka karolelano, N/(mm·μm).Lisebelisoa tsa Spur

Lisebelisoa tsa Bevel

- Phomolo ea Malebela: Ho tlosa thepa ntlheng ea leino la gear ho thibela tšitiso nakong ea ho kenya letlooeng.

- Phomolo ea Motso: Ho fetola karolo ea motso ho fokotsa khatello ea maikutlo le ho eketsa matla.

- Ho roesa moqhaka oa ketapele: Ho sebelisa leino le kobehileng hanyane ho latela bophara ba lona ho amohela ho se tsitse hantle ha leino.

- Ho roesoa ha Profaele: Ho hlahisa kobeho ho latela boemo ba involute ho fokotsa khatello ea ho kopana le moeli.

3. Lipalo tsa Moralo

Liphetoho tsa boemo ba leino la gear hangata li baloa ho sebelisoa mekhoa ea tlhahlobo, li-simulation le netefatso ea liteko. Ho nahanoa ka liparamente tse latelang:

- Chelete ea Phetoho (Δ): Botebo ba thepa e tlositsoeng holim'a leino, hangata bo tloha ho li-micron tse 5 ho isa ho tse 50 ho latela maemo a mojaro.

- Ntlha ea Kabo ea Mojaro (K): E fumana hore na khatello ea ho kopana e ajoa joang holim'a bokaholimo ba leino le fetotsoeng.

- Phoso ea Phetiso (TE): E hlalositsoe e le ho kheloha ha motsamao oa 'nete ho tloha motsamaong o loketseng, ho fokotsoa ke phetoho e ntlafalitsoeng ea profil.

- Tlhahlobo ea Li-Finite Element (FEA): E sebelisoa ho etsisa kabo ea khatello ea maikutlo le ho netefatsa liphetoho pele ho tlhahiso.

4. Mehopolo ea Moralo

- Maemo a Mojaro: Palo ea phetoho e itšetlehile ka mojaro o sebelisitsoeng le liphapang tse lebelletsoeng.

- Mamello ea Tlhahiso: Ho hlokahala ho sebetsa ka ho nepahala le ho sila ho nepahetseng ho fihlella phetoho e lakatsehang.

- Thepa ea Thepa: Ho thatafala le ho tenyetseha ha thepa ea li-gear ho susumetsa katleho ea liphetoho tsa profil.

- Tikoloho ea Ts'ebetso: Likopo tse lebelo le phahameng le tse jarang mojaro o moholo li hloka liphetoho tse nepahetseng haholoanyane.

5. Phetoho ea boemo ba meno e bohlokoa bakeng sa ho ntlafatsa ts'ebetso ea li-gear, ho fokotsa lerata, le ho ntlafatsa ho tšoarella. Phetoho e entsoeng hantle, e tšehelitsoeng ke lipalo tse nepahetseng le li-simulation, e netefatsa bolelele le katleho ea li-gear lits'ebetsong tse fapaneng.

Ka ho nahana ka maemo a mojaro, thepa ea thepa, le mekhoa ea tlhahiso e nepahetseng, baenjiniere ba ka fihlela ts'ebetso e ntle ka ho fetisisa ea lisebelisoa ha ba ntse ba fokotsa mathata a ts'ebetso.

Nako ea poso: Hlakola-11-2025