Gleasonlikere tsa bevel tse potolohangke mofuta o ikhethileng oa gear ea bevel e etselitsoeng ho fetisa matla pakeng tsa li-shaft tse kopanang, hangata ka sekhutlo sa likhato tse 90. Se etsang hore sistimi ea Gleason e ikhetholle ke mokhoa oa eona o ikhethang oa geometry ea meno le mokhoa oa tlhahiso, o fanang ka motsamao o boreleli, bokhoni bo phahameng ba torque, le ts'ebetso e khutsitseng. Gear tsena li sebelisoa haholo liphatlalatsong tsa likoloi, tsa indasteri le tsa lifofane moo ho tšepahala le ho nepahala ho leng bohlokoa.

Sistimi ea Gleason e ntlafalitsoe ho ntlafatsa ka ho toba le kali-gear tsa bevel tsa zerolka ho hlahisa leino le kobehileng, le bōpehileng joaloka lebili. Sebopeho sena sa lebili se nolofalletsa ho kopana butle-butle pakeng tsa meno, se fokotsa lerata le ho thothomela haholo ha ka nako e ts'oanang se lumella lebelo le phahameng la ho potoloha le bokhoni ba mojaro. Moralo o boetse o ntlafatsa karolelano ea ho kopana le matla a bokaholimo, ho netefatsa phetiso e sebetsang hantle ea matla tlas'a meroalo e boima kapa e matla.

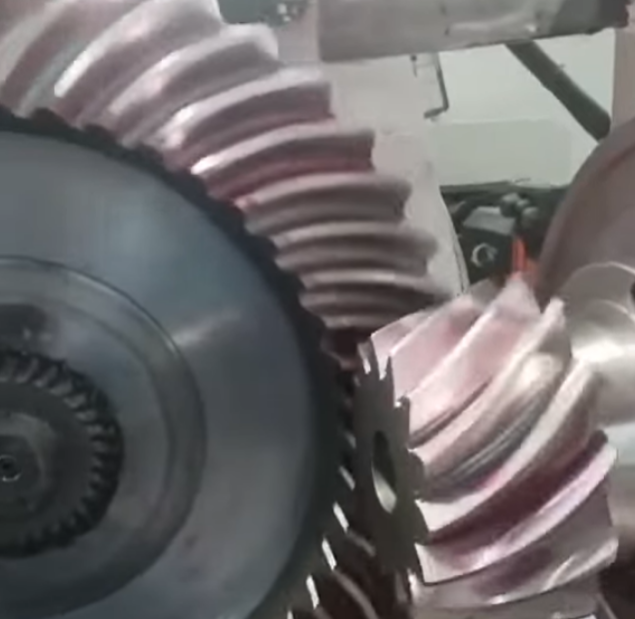

Para e 'ngoe le e 'ngoe ea li-gear tsa Gleason spiral bevel e na le pinion le gear ea ho kopanya, e hlahisoang ka jiometri e tsamaellanang. Ts'ebetso ea tlhahiso e khethehile haholo. E qala ka ho betla kapa ho lahla ka nepo likheo tsa tšepe ea alloy, tse kang 18CrNiMo7-6, e lateloa ke ho seha ka thata, ho etsa lihokelo, kapa ho bopa ho hlahisa foromo ea pele ea gear. Mekhoa e tsoetseng pele joalo ka machining ea 5-axis, ho skiing, le ho seha ka thata e netefatsa ho nepahala ho hoholo le ho qeta holimo ho ntlafalitsoeng. Kamora kalafo ea mocheso joalo ka carburization (58-60 HRC), li-gear li feta ho lapping kapa ho sila ho fihlela meshing e phethahetseng pakeng tsa pinion le gear.

Jeometri ea li-gear tsa Gleason spiral bevel e hlalosoa ke liparamente tse 'maloa tsa bohlokoa—sekhutlo sa spiral, sekhutlo sa khatello, sebaka sa khoune ea pitch, le bophara ba sefahleho. Liparamente tsena li baloa ka nepo ho netefatsa mekhoa e nepahetseng ea ho kopana le meno le kabo ea mojaro. Nakong ea tlhahlobo ea ho qetela, lisebelisoa tse kang mochini oa ho lekanya oa coordinate (CMM) le tlhahlobo ea ho kopana le meno (TCA) li netefatsa hore sete ea liparamente e fihlela sehlopha se hlokahalang sa DIN 6 kapa ISO 1328-1.

Ha e ntse e sebetsa, Gleason spiralli-bevel geare fana ka bokgoni bo phahameng le tshebetso e tsitsitseng esita le tlasa maemo a boima. Meno a kobehileng a fana ka kgokelo e tswelang pele, e fokotsang kgatello ya maikutlo le ho tsofala. Sena se etsa hore e be a loketseng dipharologanyo tsa dikoloi, di-gearbox tsa diteraka, mechini e boima, ditsamaiso tsa ho kganna tsa lewatleng, le disebediswa tsa motlakase. Ho feta moo, bokgoni ba ho iketsetsa jiometri ya meno le sebaka sa ho e kenya bo dumella baenjiniere ho ntlafatsa moralo bakeng sa dithibelo tse itseng tsa torque, lebelo le sebaka.

Gire ea bevel e spiral ea mofuta oa Gleason — tafole ea lipalo tsa senotlolo

| Ntho | Foromo / Pontšo | Mefuta-futa / Lintlha |

|---|---|---|

| Liparamente tsa ho kenya | (z_1,\ z_2,\ m_n,\ \alpha_n,\ \Sigma,\ b,\ T) | meno a pinion/gear (z); module e tloaelehileng (m_n); angle e tloaelehileng ea khatello (\alpha_n); angle ea shaft (\Sigma); bophara ba sefahleho (b); torque e fetisitsoeng (T). |

| Bophara ba referense (bohareng) | (d_i = z_i , m_n) | i = 1 (pinion), 2 (gear). Bophara ba karolelano/referense karolong e tloaelehileng. |

| Likhutlo tsa sekontiri (khoune) | (\delta_1,\ \delta_2) hoo (\delta_1+\delta_2=\Sigma) le (\dfrac{\sin\delta_1}{d_1}=\dfrac{\sin\delta_2}{d_2}) | Rarolla likhutlo tsa khoune tse lumellanang le boholo ba meno le sekhutlo sa shaft. |

| Sebaka sa khoune (sebaka se phahameng sa bophahamo ba modumo) | (R = \dfrac{d_1}{2\sin\delta_1} = \dfrac{d_2}{2\sin\delta_2}) | Sebaka ho tloha tlhorong ea khoune ho ea selikalikoe sa bophahamo se lekantsoe ho latela generatrix. |

| Sekhahla sa selikalikoe (se tloaelehileng) | (p_n = \pi m_n) | Sephetho se otlolohileng karolong e tloaelehileng. |

| Mojule o fetohang (hoo e ka bang) | (m_t = \dfrac{m_n}{\cos\beta_n}) | (\beta_n) = sekhutlo se tloaelehileng sa ho potoloha; se fetoha pakeng tsa likarolo tse tloaelehileng le tse tšekaletseng ha ho hlokahala. |

| Sekhutlo se potolohang (kamano e tloaelehileng/e potolohang) | (\tan\beta_t = \tan\beta_n \cos\delta_m) | (\delta_m) = sekhutlo se mahareng sa khoune; sebedisa diphetoho pakeng tsa dikhutlo tse tlwaelehileng, tse tshekaletseng, le tse mahareng tsa spiral. |

| Khothaletso ea bophara ba sefahleho | (b = k_b , m_n) | (k_b) hangata e khethoa ho tloha ho 8 ho isa ho 20 ho latela boholo le ts'ebeliso; sheba mokhoa oa moralo bakeng sa boleng bo nepahetseng. |

| Sehlomathiso (karolelano) | (a \hoo e ka bang m_n) | Tekanyo e tloaelehileng ea botebo bo felletseng ea tlatsetso; sebelisa litafole tse nepahetseng tsa tekanyo ea meno bakeng sa boleng bo nepahetseng. |

| Bophara ba kantle (ntlha) | (d_{o,i} = d_i + 2a) | ke = 1,2 |

| Bophara ba motso | (d_{f,i} = d_i – 2h_f) | (h_f) = dedendum (ho tloha ho tekanyo ea sistimi ea li-gear). |

| Botenya ba leino le chitja (hoo e ka bang) | (s \hoo e ka bang \dfrac{\pi m_n}{2}) | Bakeng sa jiometri ea bevel sebelisa botenya bo lokisitsoeng ho tsoa litafoleng tsa meno bakeng sa ho nepahala. |

| Matla a tangential selikalikoeng sa ho letsa | (F_t = \dfrac{2T}{d_p}) | (T) = torque; (d_p) = bophara ba bophahamo ba modumo (sebelisa diyuniti tse tsitsitseng). |

| Ho kobeha khatello ea maikutlo (e nolofalitsoeng) | (\sigma_b = \dfrac{F_t \cdot K_O \cdot K_V}{b \cdot m_n \cdot Y}) | (K_O) = ntlha e feteletseng, (K_V) = ntlha e fetohang, (Y) = ntlha ya sebopeho (jiometri e kobehang). Sebedisa equation e felletseng ya ho kobeha ya AGMA/ISO bakeng sa moralo. |

| Khatello ea maikutlo (mofuta oa Hertz, e nolofalitsoeng) | (\sigma_H = C_H \sqrt{\dfrac{F_t}{d_p , b} \cdot \dfrac{1}{\frac{1-\nu_1^2}{E_1}+\frac{1-\nu_2^2}{E_2}}}) | (C_H) jiometri e sa fetoheng, (E_i,\nu_i) thepa e tenyetsehang moduli le dikarolelano tsa Poisson. Sebedisa di-equation tse felletseng tsa kgokagano le kgatello bakeng sa netefatso. |

| Karolelano ea ho kopana (kakaretso) | (\varepsilon = \dfrac{\text{arc of action}}{\text{base pitch}}) | Bakeng sa li-gear tsa bevel bala u sebelisa jiometri ea khoune ea pitch le angle ea spiral; hangata li hlahlojoa ka litafole kapa software ea moralo oa li-gear. |

| Palo ea meno a sebele | (z_v \hoo e ka bang \dfrac{d}{m_t}) | E thusa bakeng sa ho hlahloba ho kopana/ho fokotsa ho hlaka ha di-contact; (m_t) = mojule o tshekaletseng. |

| Tlhahlobo e fokolang ea meno / ho seha meno | Sebelisa boemo bo tlase ba meno ho latela sekhutlo sa ho potoloha, sekhutlo sa khatello le boholo ba meno | Haeba (z) e le ka tlase ho bonyane, ho hlokahala ho fokotsa kapa ho sebelisa lisebelisoa tse khethehileng. |

| Litlhophiso tsa mochini/seha (mohato oa moralo) | Fumana likhutlo tsa hlooho ea seha, ho potoloha ha cradle le ho supa ho tsoa ho jiometri ea sistimi ea li-gear | Litlhophiso tsena li nkiloe ho latela geometry ea li-gear le sistimi ea seha; latela mokhoa oa mochini/lisebelisoa. |

Theknoloji ea sejoale-joale ea tlhahiso, joalo ka mechini ea ho seha le ho sila ea CNC bevel gear, e netefatsa boleng bo tsitsitseng le ho fapanyetsana. Ka ho kopanya moralo o thusoang ke khomphutha (CAD) le simulation, bahlahisi ba ka etsa boenjiniere ba morao le liteko tsa sebele pele ho tlhahiso ea 'nete. Sena se fokotsa nako ea pele le litšenyehelo ha ka nako e ts'oanang se ntlafatsa ho nepahala le ts'epo.

Ka bokhutšoanyane, li-gear tsa Gleason spiral bevel li emela motsoako o phethahetseng oa jiometri e tsoetseng pele, matla a thepa le ho nepahala ha tlhahiso. Bokhoni ba tsona ba ho fana ka phetiso ea matla e boreleli, e sebetsang hantle le e tšoarellang bo li entse karolo ea bohlokoa litsamaisong tsa sejoale-joale tsa ho khanna. Ebang li sebelisoa makaleng a likoloi, indasteri, kapa a lifofane, li-gear tsena li ntse li tsoela pele ho hlalosa bokhabane ba motsamao le ts'ebetso ea mechini.

Nako ea poso: Mphalane-24-2025