Likere tsa masale hangata li etsoa ka mokhoa o kenyeletsang mehato e 'maloa ea bohlokoa, ho kenyeletsoa ho betla kapa ho lahla, ho sebetsa ka machining,

kalafo, le ho phethela. Mona ke kakaretso ea ts'ebetso e tloaelehileng ea tlhahiso bakeng sa li-gear tsa lesale:

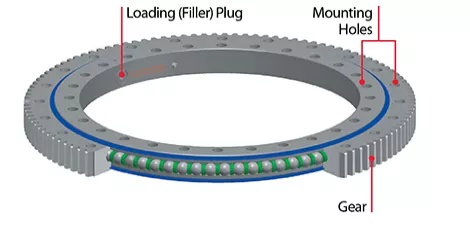

Khetho ea Thepa: Ts'ebetso e qala ka khetho ea thepa e loketseng bakeng sa li-gear tsa lesale ho latela ts'ebeliso e itseng.

litlhoko. Thepa e tloaelehileng e sebelisoang bakeng sa li-gear tsa lesale e kenyelletsa mefuta e fapaneng ea tšepe, tšepe ea motsoako, esita le litšepe tse se nang ferrous joalo ka boronse kapa

aluminium.

Ho Sebetsa kapa ho Lahlela: Ho latela thepa le bophahamo ba tlhahiso, likere tsa lesale li ka etsoa ka ho Sebetsa kapa ho Lahlela

Mekhoa. Ho betla ho kenyelletsa ho bopa di-billet tsa tshepe tse futhumaditsweng tlasa kgatello e phahameng ho sebedisa di-dies tsa ho betla ho fihlela sebopeho se lakatsehang le

litekanyo tsa thepa ea lesale. Ho lahla ho kenyelletsa ho tšela tšepe e qhibilihisitsoeng ka har'a mokoti oa hlobo, ho e lumella ho tiea le ho nka sebopeho sa hlobo.

Ho Sebetsa ka Mechini: Kamora ho betla kapa ho lahla, gia e se nang letho e sebetsa ka ho sebetsa ka mechini ho fihlela litekanyo tsa ho qetela, leino

profil, le qetello ea bokaholimo. Sena se ka kenyelletsa lits'ebetso tse kang ho reteleha, ho sila, ho phunya le ho seha li-gear ho etsa meno le tse ling

litšobotsi tsa lisebelisoa tsa lesale.

Kalafo ea Mocheso: Hang ha li-gear tsa lesale li se li entsoe ka mokhoa o lakatsehang, hangata li fuoa kalafo ea mocheso ho ntlafatsa mechini ea tsona.

litšobotsi, tse kang ho thatafala, matla le ho tiea. Mekhoa e tloaelehileng ea kalafo ea mocheso bakeng sa li-ring gear e kenyelletsa ho kenya ka har'a carburizing, ho tima,

le ho futhumatsa ho fihlela motsoako o lakatsehang oa thepa. Ho Seha Li-Gear: Mohatong ona, boemo ba leino lalisebelisoa tsa lesalee sehiloe kapa e bōpehile

ho sebelisoa mechine e khethehileng ea ho seha lisebelisoa. Mekhoa e tloaelehileng e kenyelletsa hobing, ho bopa, kapa ho sila, ho latela litlhoko tse itseng tsa

moralo oa lisebelisoa.

Taolo ea Boleng: Nakong eohle ea ts'ebetso ea tlhahiso, mehato e matla ea taolo ea boleng e kenngoa tšebetsong ho netefatsa hore li-giers tsa lesale

ho fihlela litlhaloso le maemo a hlokahalang. Sena se ka kenyelletsa tlhahlobo ea boholo, liteko tsa thepa, le liteko tse sa senyeheng

mekhoa e kang tlhahlobo ea ultrasound kapa tlhahlobo ea likaroloana tsa makenete.

Mesebetsi ea ho Qetela: Kamora kalafo ea mocheso le ho khaola li-gear, li-gear tsa selikalikoe li ka etsoa mesebetsi e meng ea ho qetela ho ntlafatsa bokaholimo.

ho nepahala le ho hlaka ha sebopeho. Sena se ka kenyelletsa ho sila, ho honotha, kapa ho kopanya ho fihlela boleng ba ho qetela ba bokaholimo bo hlokahalang bakeng sa

ts'ebeliso.

Tlhahlobo ea ho Qetela le ho Paka: Hang ha mesebetsi eohle ea tlhahiso le ea ho qeta e phethetsoe, likere tsa lesale tse felileng li feta ho ea ho qetela

tlhahlobo ho netefatsa boleng ba tsona le ho latela litlhaloso. Kamora tlhahlobo, likere tsa lesale hangata lia pakoa le ho lokisetsoa

ho romelloa ho bareki kapa ho kopanngoa ka har'a liboka kapa litsamaiso tse kholo tsa lisebelisoa.

Ka kakaretso, ts'ebetso ea tlhahisolikere tsa ho tjhesae kenyelletsa motsoako oa ho betla kapa ho lahla, ho sebetsa ka machining, kalafo ea mocheso le ho qeta

mesebetsi ea ho hlahisa likarolo tsa boleng bo holimo tse loketseng lits'ebetso tse fapaneng tsa indasteri. Mohato o mong le o mong ts'ebetsong o hloka tlhokomelo

ela hloko lintlha tse qaqileng le ho nepahala ho netefatsa hore lihlahisoa tsa ho qetela li fihlela maemo a hlokahalang bakeng sa ts'ebetso le ts'epo.

Nako ea poso: Phuptjane-14-2024