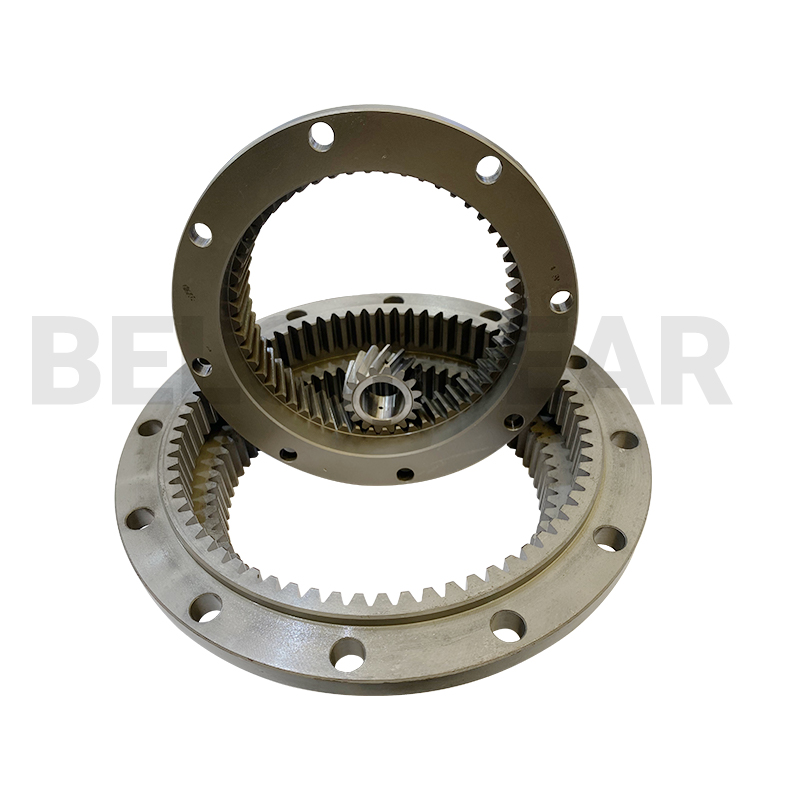

Li-gear tsa kahareke mofuta oa gear moo meno a sehiloeng ka hare ho silindara kapa khoune, ho fapana le gear tsa kantle moo meno a leng ka ntle. Li kopanya letlooeng ka gear tsa kantle, 'me moralo oa tsona o li nolofalletsa ho fetisa motsamao le matla litsamaisong tse fapaneng tsa mechini.

Ho na le lits'ebetso tse 'maloa bakeng sa li-gear tsa kahare:

- Mekhoa ea Lisebelisoa tsa Lipolanete: Li-gear tsa ka hare li sebelisoa hangata litsamaisong tsa lisebelisoa tsa lipolanete, moo li kopanang le lisebelisoa tsa letsatsi le li-gear tsa lipolanete. Tokisetso ena e lumella literene tsa lisebelisoa tse nyane le tse feto-fetohang, tse atisang ho sebelisoa li-transmission tsa likoloi le mechini ea indasteri.

- Phetiso ea Matla: Li-gear tsa kahare li ka sebelisoa ho fetisa matla pakeng tsa li-shaft tse bapileng kapa tse kopanang. Hangata li sebelisoa maemong ao lithibelo tsa sebaka kapa litlhoko tse itseng tsa torque li hlokang hore li sebelisoe.

- Phokotso ea Lebelo kapa Keketseho: Li-gear tsa kahareli ka sebelisoa ho eketsa kapa ho fokotsa lebelo la ho potoloha ho latela sebopeho sa tsona le ho li kopanya ka li-gear tsa kantle.

- Taolo ea Motsamao: Lirobotong le boiketsetso, li-gear tsa kahare li sebelisoa bakeng sa taolo e nepahetseng ea motsamao, ho netefatsa motsamao o boreleli le o nepahetseng matsohong a roboto, mechini ea CNC, le litsamaiso tse ling tse iketsang.

- Mekhoa e Fapaneng: Li-gear tsa kahare li ka boela tsa fumanoa mekhoeng e fapaneng, joalo ka e sebelisoang litereneng tsa ho khanna tsa likoloi, ho aba matla le torque lipakeng tsa mabili ha li ntse li a lumella ho potoloha ka lebelo le fapaneng.

- In liroboto le boiketsetso, li-gear tsa kahare li sebelisoa haholo ho fihlela metsamao e nepahetseng ka har'a libaka tse fokolang. Matsoho a roboto, mohlala, hangata a sebelisa li-gear tsa kahare ho li-actuator tsa ona ho fana ka sebaka se nepahetseng ka ho fokotsa ho khutlela morao, ho nolofalletsang motsamao o boreleli le o laoloang haholoanyane. Tlhaho e kopaneng ea li-gear tsa kahare e thusa baenjiniere ho kopanya litsamaiso tse rarahaneng tsa li-gear likopanong tse nyane, e leng se lumellang liroboto ho boloka boemo bo phahameng ba ho ba bonolo le bokgabane ntle le ho tela matla kapa taolo.

- Li-gear tsa kahare hape ke khetho e tsebahalang haholo holikoloi tsa motlakase (li-EV), haholo-holo ka har'a li-gearbox tse etselitsoeng ho sebetsana le lebelo le phahameng la ho potoloha. Hangata li-engine tsa EV li sebetsa ka lebelo le phahameng haholo ho feta lienjene tsa ho chesa ka hare, kahoo li-gear tsa kahare, hammoho le litsamaiso tsa li-gear tsa polanete, li bohlokoa bakeng sa ho fokotsa lebelo ha li ntse li eketsa torque. Setha sena se ntlafatsa ts'ebetso ea matla, e leng se lebisang ho phanong e boreleli ea matla le bophelo bo bolelele ba betri.

- In mechine ea khatisolemechine ea masela, moo ho nepahala ho hoholo ho leng bohlokwa, di-gear tsa kahare di sebediswa ditsamaisong tse hlokang ho boloka ho potoloha le lebelo le tsamaellanang. Setaele sa di-gear tsa kahare se thusa ho fihlella botsitso le ho nepahala ha motsamao, se tlatsetsa boleng ba sehlahiswa sa ho qetela, ebang ke thepa e hatisitsweng kapa masela. Sebopeho sa tsona se kopaneng le bokgoni bo sebetsang ba ho arolelana mojaro di nolofalletsa metjhini ena ho sebetsa ka lebelo le phahameng ntle le ho beha kotsing ya ho se tsamaellane hantle kapa ho senyeha ho feteletseng.

Ho phaella moo,lisebelisoa tsa bongakajoalo ka liroboto tsa opereishene le litsamaiso tsa litšoantšo hangata li sebelisa li-gear tsa kahare ka har'a li-actuator tsa tsona bakeng sa motsamao o nepahetseng le o laoloang ka har'a libaka tse nyane. Li-gear tsa kahare li thusa ho boloka ho nepahala le botsitso, tse bohlokoa bakeng sa ts'ebetso e bonolo, tlhahlobo ea mafu le polokeho ea mokuli.

Moralo le tlhahiso ea li-gear tsa kahare e ka ba tse rarahaneng ho feta li-gear tsa kantle ka lebaka la bothata ba ho fihlella kahare ho li-gear nakong ea ho sebetsa. Leha ho le joalo, li fana ka melemo lits'ebetsong tse itseng, joalo ka ho ba bonolo, bokhoni bo eketsehileng ba phetisetso ea torque, le ts'ebetso e boreleli.

Nako ea poso: Mmesa-30-2024