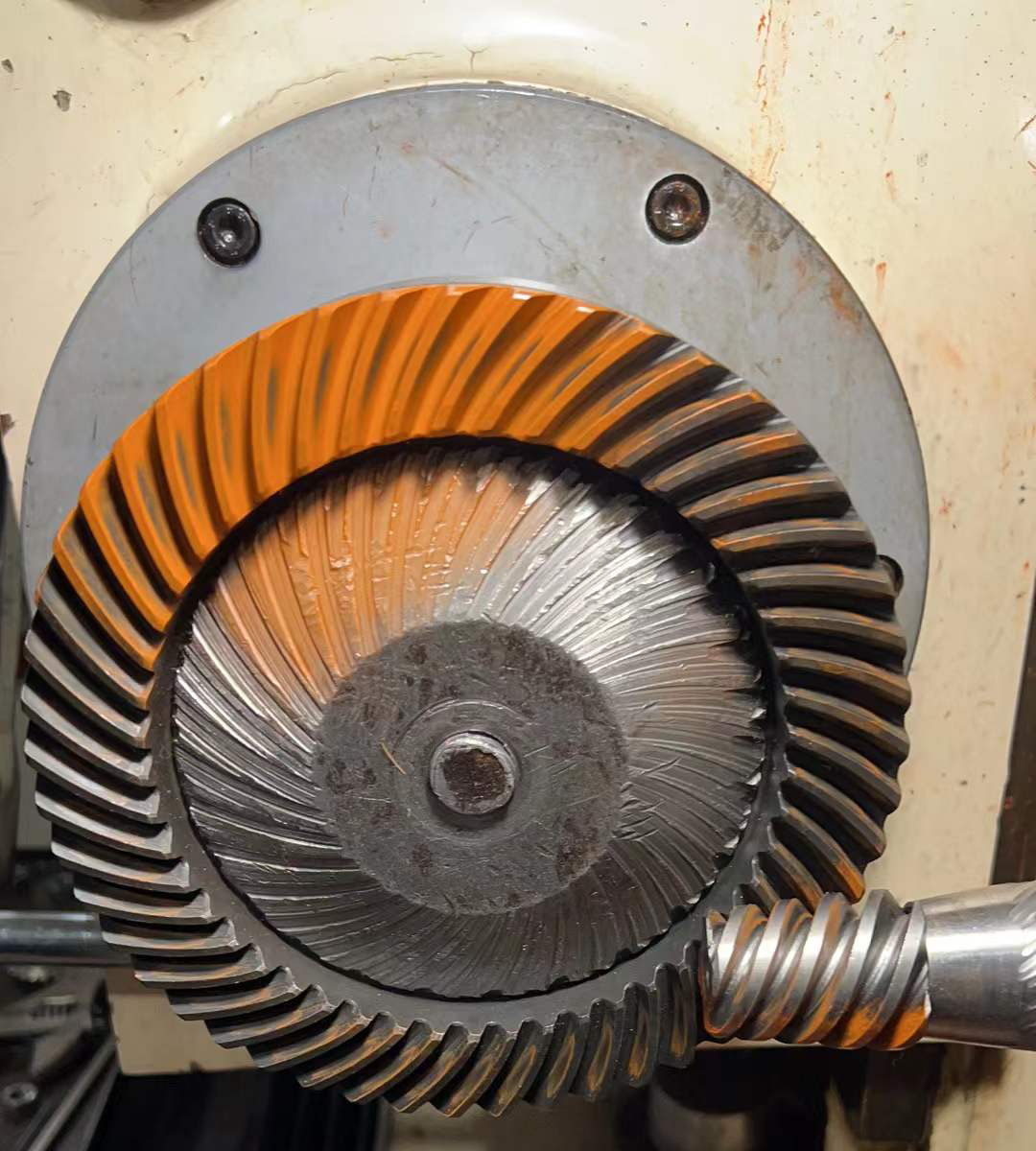

Ho na le mefuta e mengata ea likere, ho kenyeletsoa likere tse otlolohileng tsa cylindrical, likere tsa helical cylindrical, likere tsa bevel, le likere tsa hypoid tseo re li hlahisang kajeno.

1) Litšobotsi tsa lisebelisoa tsa hypoid

Pele ho tsohle, angle ea shaft ea gear ea hypoid ke 90 °, 'me tataiso ea torque e ka fetoloa ho 90 °.Hona hape ke phetoho ea li-angle hangata e hlokahalang indastering ea motlakase ea likoloi, tsa sefofane kapa tsa moea.Ka nako e ts'oanang, li-gears tse nang le boholo bo fapaneng le linomoro tse fapaneng tsa meno li kenngoa ka marang-rang ho leka mosebetsi oa ho eketsa torque le lebelo le fokotsehang, leo hangata le bitsoang "torque e ntseng e eketseha le ho fokotseha lebelo".Haeba motsoalle ea kileng a khanna koloi, haholo-holo ha a ntse a khanna koloi ea matsoho ha a ntse a ithuta ho khanna, ha a hloa leralleng, morupeli o tla u lumella hore u tsamaee ka gear e tlaase, ha e le hantle, ke ho khetha para ea likere tse nang le lisebelisoa tse batlang li lekana. lebelo le leholo, le fanoang ka lebelo le tlase.Torque e eketsehileng, kahoo e fana ka matla a eketsehileng koloing.

Litšobotsi tsa lisebelisoa tsa hypoid ke life?

Liphetoho ka lehlakoreng la torque ea phetiso

Joalokaha ho boletsoe ka holimo, phetoho ea angular ea matla a torque e ka phethahala.

E khona ho mamella meroalo e meholoanyane

Ka indasteri ea matla a moea, indasteri ea likoloi, ebang ke likoloi tsa baeti, li-SUV, kapa likoloi tsa khoebo tse kang literaka, literaka, libese, joalo-joalo, li tla sebelisa mofuta ona ho fana ka matla a maholo.

Phetiso e tsitsitseng haholoanyane, lerata le tlase

Li-angles tsa khatello ea mahlakoreng a letšehali le a ka ho le letona a meno a eona a ka ba a sa lumellaneng, 'me tsela e thellang ea gear meshing e haufi le bophara ba leino le tataiso ea boemo ba leino,' me sebaka se betere sa meshing se ka fumanoa ka moralo le theknoloji. phetiso eohle e tlas'a mojaro.E latelang e ntse e le ntle haholo ts'ebetsong ea NVH.

Sebaka se feto-fetohang sa offset

Ka lebaka la moralo o fapaneng oa sebaka sa offset, e ka sebelisoa ho fihlela litlhoko tse fapaneng tsa moralo oa sebaka.Ka mohlala, tabeng ea koloi, e ka finyella litlhoko tsa tumello ea fatše ea koloi le ho ntlafatsa bokhoni ba ho feta ba koloi.

2) Mekhoa e 'meli ea ho sebetsana le lisebelisoa tsa hypoid

Thepa e nang le mahlakore a mabeli e ile ea hlahisoa ke Gleason Work 1925 'me e 'nile ea ntlafatsoa ka lilemo tse ngata.Hona joale, ho na le lisebelisoa tse ngata tsa malapeng tse ka sebelisoang, empa ts'ebetso e batlang e nepahetse le e phahameng e etsoa haholo-holo ke thepa ea linaheng tse ling Gleason le Oerlikon .Mabapi le ho qeta, ho na le mekhoa e 'meli e meholo ea ho sila le mekhoa ea ho sila, empa litlhoko tsa mokhoa oa ho khaola li-gear li fapane. to face hobbing .

Li-gears tse sebetsoang ke mofuta oa ho sila sefahleho ke meno a theohileng, 'me likere tse sebetsoang ke mofuta oa sefahleho ke meno a bolelele bo lekanang, ke hore, bophahamo ba meno lifahlehong tse kholo le tse nyane li tšoana.

Mokhoa o tloaelehileng oa ts'ebetso ke hoo e batlang e le ho futhumatsa pele, ka mor'a phekolo ea mocheso, ebe o qeta.Bakeng sa mofuta oa hob ea sefahleho, e hloka ho thellisoa le ho ts'oaroa ka mor'a ho futhumatsa.Ha e le hantle, li-gear tse peli tse fatše li lokela ho bapisoa ha li kopantsoe hamorao.Leha ho le joalo, ka khopolo, likere tse nang le theknoloji ea ho sila li ka sebelisoa ntle le ho bapisa.Leha ho le joalo, ts'ebetsong ea 'nete, ho nahanoa ka tšusumetso ea liphoso tsa kopano le deformation ea tsamaiso, mokhoa o ts'oanang o ntse o sebelisoa.

3) Moralo le nts'etsopele ea li-triple hypoid li rarahane haholo, haholo-holo maemong a ts'ebetso kapa lihlahisoa tse phahameng tse nang le litlhoko tse phahameng, tse hlokang matla, lerata, katleho ea phetisetso, boima le boholo ba lisebelisoa.Ka hona, sethaleng sa moralo, hangata hoa hlokahala ho kopanya lintlha tse ngata ho fumana tekanyo ka ho pheta-pheta.Ts'ebetsong ea nts'etsopele, hangata hoa hlokahala ho lokisa khatiso ea leino ka har'a mefuta e fapaneng e lumelletsoeng ea kopano ho netefatsa hore boemo bo nepahetseng ba ts'ebetso bo ntse bo ka fihlelleha tlasa maemo a nnete ka lebaka la ho bokelloa ha ketane ea dimensional, deformation ea sistimi le lintlha tse ling.

Nako ea poso: May-12-2022